Integrated Circuit Programming – Reliable IC Burning and Configuration Services

Modern electronics depend on precise and efficient programming to function as intended. Integrated Circuit Programming plays a critical role in configuring chips with the right data, firmware, or instructions before they are deployed in various applications. From consumer electronics to industrial machinery, this process ensures that every device operates with the exact logic and performance required by its design.

The Importance of Accurate IC Programming

Every integrated circuit serves a specific purpose within a larger electronic system. Whether it’s controlling a display, processing sensor data, or managing communication protocols, the chip must be programmed with the correct code. Integrated Circuit Programming ensures that these instructions are loaded accurately, minimizing the risk of malfunction and guaranteeing reliable performance. This accuracy becomes especially important in industries where even the smallest errors can lead to costly downtime or product recalls.

How IC Burning and Configuration Work

The process begins with receiving the necessary programming data from the client or development team. This information is then transferred into the integrated circuit through specialized equipment, often referred to as IC burners or programmers. Integrated Circuit Programming may involve one-time programmable (OTP) devices, flash memory, or other reprogrammable chips, depending on the project’s requirements. After the programming is complete, verification steps ensure the data has been correctly written and the IC is ready for deployment.

Benefits of Professional IC Programming Services

Working with experienced specialists in Integrated Circuit Programming offers several advantages. First, it reduces the risk of errors by using advanced programming systems that handle high volumes without compromising accuracy. Second, it ensures consistent results, even when working with large production runs. Finally, it streamlines the manufacturing process by integrating programming into the assembly workflow, saving both time and resources.

Meeting the Demands of Different Industries

Electronics manufacturers in automotive, aerospace, telecommunications, and consumer goods all rely on Integrated Circuit Programming to bring their products to life. In the automotive sector, microcontrollers control everything from engine performance to infotainment systems. In telecommunications, programmable ICs manage network switching and signal processing. By providing reliable IC burning and configuration, programming services make sure these components are ready for immediate integration into final products.

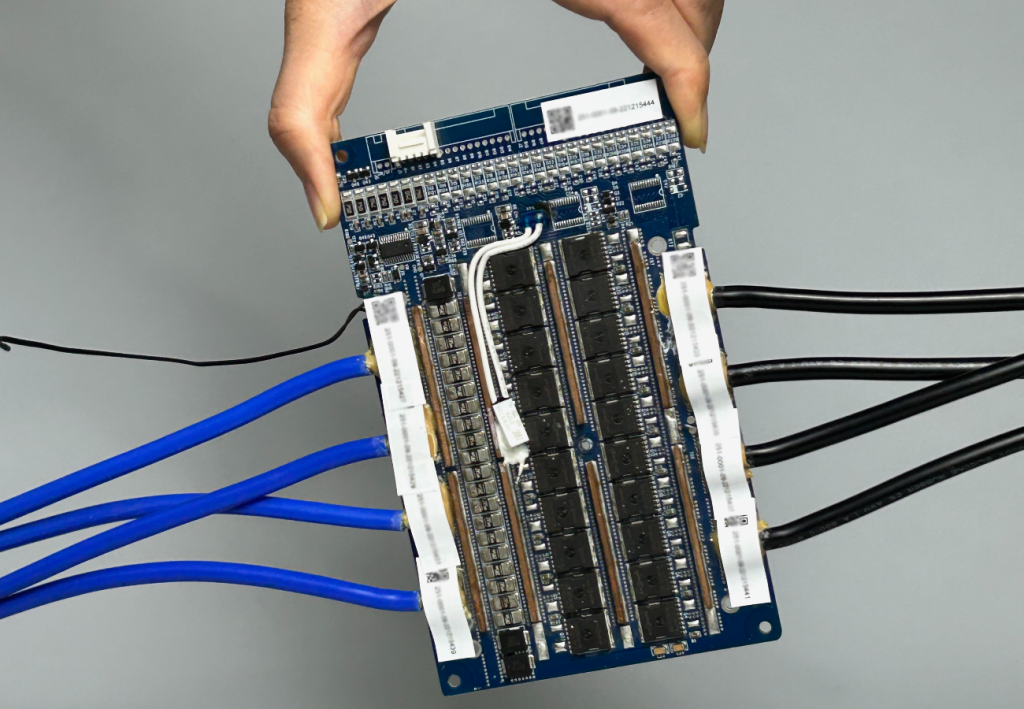

Advanced Equipment for High-Precision Programming

Modern programming facilities use sophisticated IC burning equipment capable of handling various package types and pin configurations. This allows Integrated Circuit Programming to support a wide range of chips, including surface-mount devices, through-hole components, and fine-pitch packages. With automated handlers and testing systems, these facilities can process thousands of units quickly while maintaining strict quality standards.

Quality Control and Verification

Reliability is essential in electronics manufacturing, and programming is no exception. Every chip that goes through Integrated Circuit Programming undergoes verification to confirm that the programmed data matches the original file exactly. This step helps prevent costly defects and ensures that the final product performs as intended. In high-volume production environments, automated quality control systems provide the speed and precision necessary to keep up with demand.

Cost and Time Efficiency in Production

Integrating programming directly into the manufacturing line can significantly reduce production time. Instead of shipping components to a separate facility for burning and configuration, Integrated Circuit Programming can be performed on-site or as part of the PCB assembly process. This eliminates additional handling, reduces logistics costs, and speeds up time-to-market without sacrificing quality.

The Future of IC Programming

As electronic devices become more complex, Integrated Circuit Programming will continue to evolve to handle larger code sizes, faster write speeds, and more sophisticated security features. The demand for secure programming—ensuring that firmware and proprietary code cannot be tampered with—will also grow. By choosing a service provider with advanced capabilities and a strong focus on quality, manufacturers can ensure their products are built on a foundation of reliability and performance.